Preliminary Remarks:

Franz Josef Radermacher and Tobias Orthen (both GES und FAW/n) are working with the Council of Engineers for the Energy Transition (CEET). This article summarizes the key findings of the CEET’s Policy Brief on Carbon Capture and Usage/Storage which will officially be released soon. First findings were already presented in a panel discussion moderated by T. Orthen at the 29 UN Climate Conference in Baku 2024.

The CEET is a “global high-level body of engineers and energy systems experts contributing to the UN Secretary-General’s goal of building a coalition to achieve net-zero emissions by 2050. The CEET was launched in September 2021 and is co-chaired by Dr. Gerd Müller, Director General of the United Nations Industrial Development Organization (UNIDO), and Professor Jeffrey Sachs, President of the UN Sustainable Development Solutions Network (SDSN).

Introduction: The Growing Need for CCS

The world is at a critical turning point in the fight against climate change. In 2022 alone, global carbon dioxide (CO₂) emissions from energy and industry reached an alarming 37 gigatons, with power generation, manufacturing, and transportation sectors contributing the most. Despite rapid advancements in renewable energy, such as wind and solar, global dependence on fossil fuels remains high, especially in heavy industries where alternatives are still developing.

While energy efficiency and electrification are essential, they are not enough to reduce emissions to the levels needed to meet global climate goals. Carbon Capture and Storage (CCS) technology has emerged as a crucial solution to bridge this gap by capturing emissions at the source and either repurposing or storing them safely underground. Many climate experts agree that without large-scale CCS deployment, achieving net-zero emissions by mid-century will be nearly impossible.

What is CCS and How Does It Work?

CCS is a process designed to capture CO₂ emissions from power plants, industrial facilities, and other major sources before they enter the atmosphere. The process consists of three main steps:

- Capture – CO₂ is separated from gases produced in industrial activities or power generation. Different methods are used for this, including chemical absorption, membrane separation, and cryogenic processes.

- Transport – Once captured, the CO₂ is compressed and transported through pipelines, ships, or trucks to designated storage sites.

- Storage – The CO₂ is permanently stored underground in geological formations such as depleted oil and gas fields or deep saline aquifers.

There is also Carbon Capture, Utilization, and Storage (CCUS), where captured CO₂ is repurposed for industrial applications, such as synthetic fuels, chemicals, and even concrete production. However, if not bound permanently, CO₂ from utilization may eventually return to the atmosphere.

Current State of CCS: Global Growth and Industry Adoption

CCS technology has seen rapid growth in recent years. In 2024, there were 50 operational CCS facilities worldwide, with another 44 under construction and over 500 projects in various development stages. This surge in projects signals increasing confidence in CCS as a viable climate solution.

Certain industries are particularly reliant on CCS due to their inherent emissions and the lack of viable alternatives:

- Cement and Steel Production – These industries account for nearly 15% of global CO₂ emissions. Unlike energy generation, emissions from these sectors come from chemical reactions. Therefore, it is not enough to simply switch to renewable energy. Instead, the whole production process needs to be taken into account. This is why CCS is especially interesting in this sector as it can be added at the end of the process chain. For further information see the CEET Policy Briefs on Cement and Steel. The latter will be officially published soon. The main CEET-authors are F. J. Radermacher, T. Orthen together with N. Ahlawat from Jindal Steel, India.

- Chemical Manufacturing – Production of hydrogen and ammonia generates substantial CO₂. CCS allows for cleaner hydrogen (often called “blue hydrogen”) by capturing emissions from the production process.

- Energy Sector – Fossil fuel power plants, especially coal and natural gas, can significantly cut their emissions with CCS, helping nations transition to lower-carbon energy sources while maintaining reliability.

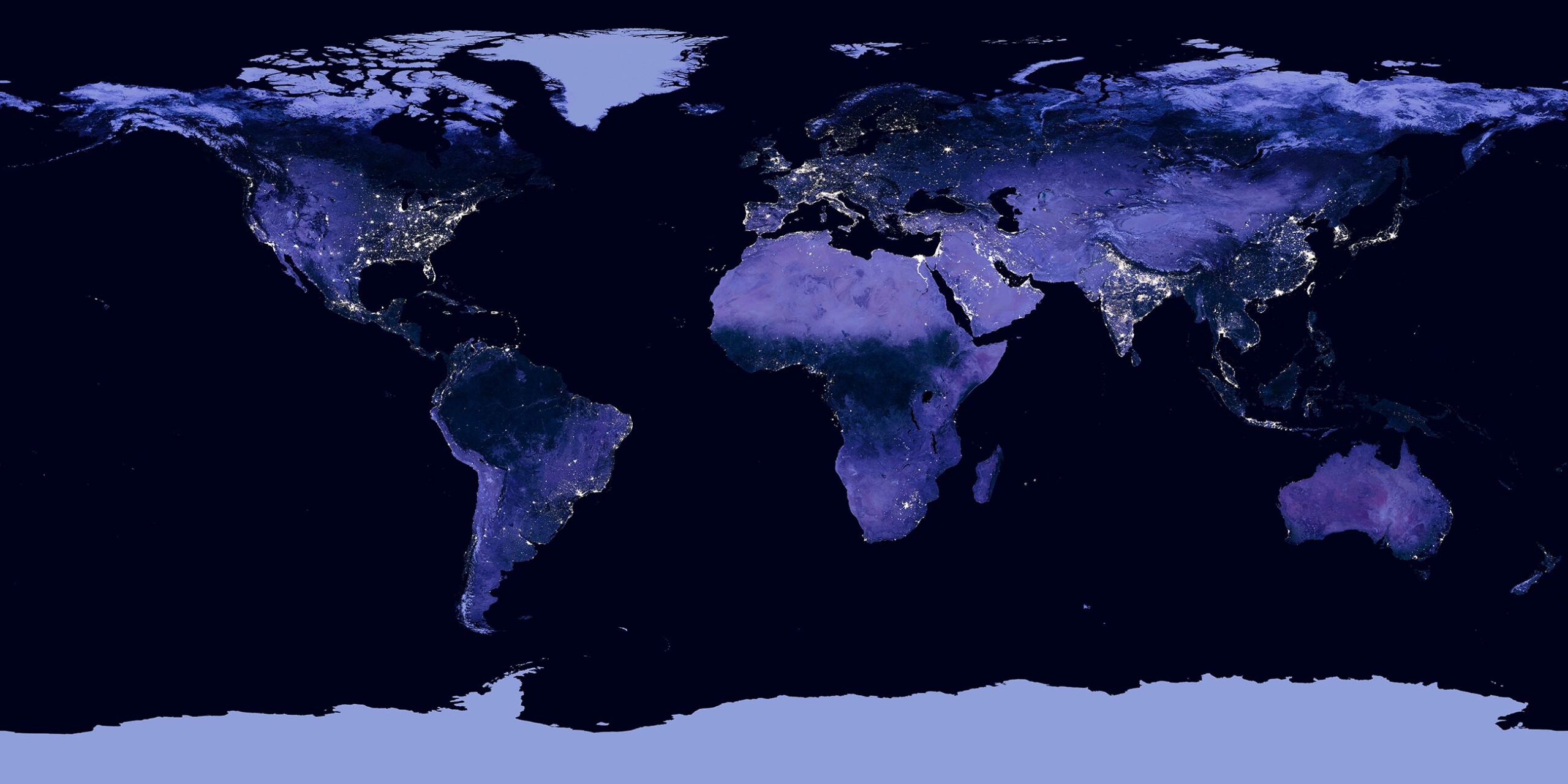

Graphic 1(see PDF)

Challenges Facing CCS Deployment

Despite its potential, CCS faces several hurdles that must be overcome to scale effectively:

1. Costs and Financial Barriers

One of the biggest challenges is cost. Capturing and storing CO₂ can be expensive, with costs varying depending on factors such as CO₂ concentration, transportation distance, and storage site characteristics. Currently, estimates suggest that the cost of CCS can range from $50 to $100 per ton of CO₂ avoided. In addition, the technical efficiency of the basic processes deteriorates by 5–10 percentage points, which also affects the profitability of the projects.

Governments and organizations are working on financial incentives to make CCS more economically viable, such as carbon pricing mechanisms that charge companies for emissions, making CCS a cost-effective alternative. Also, tax credits and subsidies (e.g., the U.S. Inflation Reduction Act offers $85 per ton of CO₂ stored) are discussed as well as investment in CCS hubs, which share infrastructure among multiple companies to reduce costs.

Graphic 2(see PDF)

2. Public Perception and Skepticism

CCS has faced skepticism, with some viewing it as a way for fossil fuel industries to prolong their operations rather than transitioning to cleaner alternatives. It should be borne in mind that more than 75 per cent of the energy used worldwide is currently still based on fossil fuels and that it will not be possible to do without these energy sources on a global scale for decades due to the economic interests of producers and consumers. In addition, experts argue that CCS is a necessary tool for industries where emissions are unavoidable. Effective communication and public engagement are essential to gaining trust in CCS initiatives.

3. Regulatory and Legal Barriers

The legal framework for CO₂ storage and transportation is still evolving. One key challenge is that CO₂ sources and storage sites are often located in different countries, requiring cross-border agreements and regulatory alignment. For example, Germany plans to export captured CO₂ to Norway for offshore storage, but current EU regulations pose hurdles to such international collaborations. However, even in Germany relevance for CCUS has been increasing recently, e.g. through the adoption of the so-called Carbon Management Strategy of the Federal Government in early 2024.

The Role of CCS in Carbon Markets (Article 6 of the Paris Agreement)

One promising avenue for CCS financing is carbon credit markets. Article 6 of the Paris Agreement allows countries to trade emissions reductions, meaning companies or nations that invest in CCS can earn credits that can be sold to others needing to offset their emissions.

- Article 6.2 – Allows countries to cooperate on emissions reductions by trading credits.

- Article 6.4 – Enables businesses and individuals to invest in emission reduction projects (including CCS) in return for carbon credits.

However, challenges remain, such as determining how to properly account for CO₂ that is captured in one country but stored in another. International collaboration is needed to develop clear accounting rules and market incentives for CCS.

Innovations and Future Outlook

To accelerate CCS adoption, technological innovations are making the process more cost-effective and efficient. Firstly, advanced materials, e.g. new solvent and membrane technologies, are improving CO₂ capture efficiency while reducing energy requirements. Secondly, CCS hubs and clusters gain importance, meaning large-scale CCS networks, such as those in the UK and Norway which are reducing costs by sharing infrastructure among industries.

Conclusion: The Road Ahead for CCS

As the world races to meet net-zero targets by 2050, CCS will play a critical role in reducing emissions from hard-to-abate industries. While challenges remain, increasing investment, policy support, and technological advancements are making CCS a more viable and essential climate solution. CCS is necessary for decarbonizing industries like cement, steel, and chemicals. Over 50 commercial CCS facilities are already operational, with many more on the way. Financial incentives, regulatory reforms, and public awareness are key to CCS success. Innovations are making CCS more efficient and cost-effective. With growing global momentum, CCS is no longer just an experimental technology—it is a cornerstone of the clean energy transition.

Sources cited in PDF: Global CCS Institute, 2024. Global status of CCS 2024. https://www.globalccsinstitute.com/wp-content/uploads/2024/10/Global-Status-Report-2024-Interactive.pdf; DNV Energy transition outlook 2023. https://www.dnv.com/energy-transition-outlook/download