Grafik 1(siehe PDF-Dokument)

Preliminary remark

As part of the decarbonisation of Germany’s overall energy consumption, combustion processes for generating heat in buildings and industrial and commercial process heat are being replaced by processes that require the use of electrical energy.

Taking into account all efficiency improvements resulting from the use of ambient heat from the air, water and ground, as well as the utilisation of industrial waste heat, this results in a tripling of electricity demand to around 1,500 TWh per year by 2045 if the final consumption of energy remains stable over this period. In fact, it must be assumed that part of the manufacturing sector and industry will either give up production or relocate it abroad. Furthermore, not all processes are likely to be decarbonised. For this reason, future electricity demand is expected to be only 800 to 1,000 TWh, which is roughly double the amount in 2025.

If we think about the future demand for artificial intelligence (AI) applications, doubling the electricity requirement represents a lower limit.

Electrical energy must be reliably available. This means that the daily fluctuations of photovoltaics and the seasonal profiles of photovoltaics and wind energy must be balanced out by storage systems with unprecedented capacity. Pumped storage power plants, compressed air storage, hydrogen storage and batteries are already available today on a scale that has been far too small to date. Whether they can be expanded to the required extent is highly doubtful. Efficiency losses and investment costs clearly speak against it.

Another conceivable solution is the cross-regional exchange of electricity with neighbouring countries. But here, too, the question must be asked as to why they should build controllable capacities for Germany for the winter, when energy demand is particularly high and the supply capacity of photovoltaics is particularly low, which are only needed for a few months of the year.

In this respect, it makes sense to think about setting up a separate controllable generation capacity. Due to the potential for heat extraction for district heating systems and process steam supply, this should be installed close to the consumers. It should not be based on combustion processes of carbon-containing primary energy or be equipped with processes to remove CO2 from the exhaust gases through CCS or CCU. Finally, due to the advantages of decentralised and therefore grid-friendly energy supply, the respective capacity should be adapted to the needs of the respective environment. The technology used should not have a negative impact on the environment – in particular, it should not harbour any risks with regard to the release of hazardous substances, nor should it give rise to disposal tasks that will burden generations of future generations with safe storage.

With the aim of fulfilling all these requirements, a large number of projects for the development of small modular nuclear reactors (SMRs) have been initiated worldwide. The aim of this report is to present the essential information on these projects and to publicise the most important features.

This work was strongly orientated towards the publications of the International Energy Agency (IEA) (2) and the International Atomic Energy Agency (IAEA) (5). In particular, several statements and graphics were adopted 1:1 after checking the content.

This report also describes the technical principles, special designs and potential applications of SMR.

Global Energy Solutions has already published the chapter “Generation of electricity from nuclear power” as part of the basic documentation of the BMZ-funded project “Global Energy Perspectives” (1). This dealt with various aspects of mainly conventional nuclear energy applications: Reactor types, nuclear fuels, reactor safety, waste management, proliferation, etc. These topics are referred to in this report.

Nuclear energy as climate-neutral energy

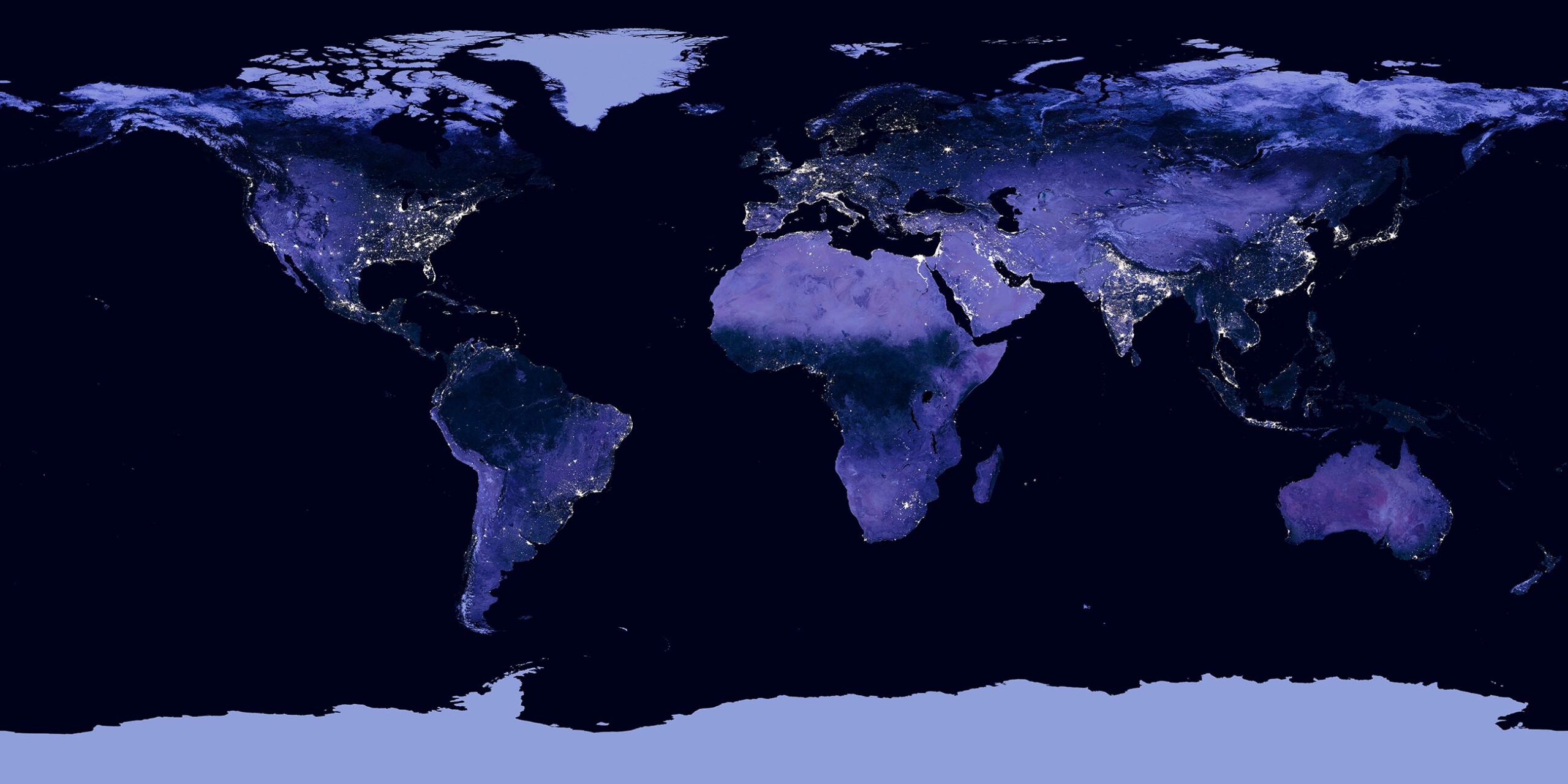

Nuclear energy is the second largest source of low-emission electricity after hydropower (Fig. 1). In 2023, it generated 20 % more energy than wind energy and 70 % more than photovoltaics and also supplies process heat for industry, as well as district heating and energy for desalination plants in several countries.

Since 1971, nuclear energy has avoided 72 Gt of CO2 emission reducing the need for fossil fuels to generate electricity, process heat and district heating. There are currently 410 nuclear reactors in operation worldwide. They generate 9% of the electricity required and therefore avoid around 1.5 Gt of CO2 emissions of the annual 37 Gt of CO2 emissions.

Grafik 2(siehe PDF-Dokument)

The proportionate importance of energy use for various production processes can be roughly estimated based on the share of energy costs relative to turnover. The chemical industry, the production of aluminium, copper and high-alloy steels as well as IT are particularly energy-intensive. The latter is currently on the rise due to the imminent use of artificial intelligence.

The large IT companies are focussing more and more on low-emission energy supply for reasons of the transparency required for the environmental statement and are using this as a differentiating feature from their competitors. More and more customers are now demanding climate-neutral computing power from IT companies.

Global utilisation of conventional nuclear energy

Since the first industrial nuclear fission in 1954, nuclear energy has become an important part of many countries’ energy systems. Its contribution to meeting energy demand, which initially rose sharply each year, was curbed by the Chernobyl reactor disaster in 1986. The rapid development of photovoltaics and wind turbines as well as the decline in energy demand in many industrialised nations due to efficiencies and the migration of manufacturing companies had an impact on the subsequent rate of expansion.

Global investment in nuclear energy was therefore declining at the turn of the century, particularly in the advanced economies. In addition to growing concerns among sections of the population about the dangers posed by the plants, despite demonstrably good statistical data on safety (number of deaths per kWh of electrical energy generated), there were major problems due to construction time extensions and cost overruns in various projects – particularly in Europe – which had a negative impact on the image. The issue of waste disposal also plays a special role. Only recently have sites for final repositories been established in Finland and Switzerland.

The German Repository Search Act was formulated out of fear on the part of politicians in such a way that it is not possible to determine a site, because the requirements are not already fulfilled when a site proves to be suitable, but only when it is certain that there is no other site in the whole of Germany that is even more suitable.

The increase in electrical energy requirements for the decarbonisation of most thermal processes and for data centres and computers, whose hunger for energy is growing due to the use of artificial intelligence, is leading to a rethink.

The strategy of avoiding anthropogenic contributions to global warming is leading to the decarbonisation of many processes:

- Heat for buildings and process heat is raised from environmental heat – geothermal, aquathermal or aerothermal – and from industrial waste heat to the temperature level required for the respective application using electrically driven heat pumps.

- Traction energy in mobility is generated electrically or by using hydrogen, which should preferably be provided from “green” electrical energy.

Based on complete decarbonisation, electricity demand in Germany would triple in the future and the combustion of coal, oil and natural gas would be completely eliminated, with the exception of power plant processes. In reality, however, a maximum doubling is expected, as various processes will continue to be supported by fossil fuels and because a large proportion of industrial and commercial production will be relocated to neighbouring countries with nuclear power or to geographical areas with a high proportion of renewable energy. In addition to Canada, the African countries of Ethiopia, the Central African Republic, the Congo and Namibia, which all have large shares of hydropower and, in some cases, a very high potential for photovoltaics, are suitable candidates.

In addition to the growing use of photovoltaics (PV) and wind energy, concerns about a reliable economic energy supply are triggering measures to utilise controllable low-emission electricity capacities: nuclear energy is therefore being used again worldwide.

Nuclear energy is also becoming particularly attractive due to the recent success of prototype applications for the next generation of plants.

Nuclear energy is therefore playing an increasingly important role in advanced economies (3) and will account for around 9 % of global electricity supply in 2023.

Shortly before the turn of the millennium (1997), the current production of electricity from nuclear power plants corresponded to around 17.5 % of global electricity demand, which has roughly doubled since then, while the construction of new nuclear power plants can only be seen as a replacement for decommissioned plants, meaning that the absolute production volume has remained roughly constant.

The use of nuclear energy is the only way to keep electricity prices stable and thus prevent the migration of production. Nineteen countries now use reactors (Fig. 2). Other countries are deciding to reverse the decision they once made to phase out nuclear power or are entering the peaceful utilisation of nuclear energy for the first time.

The technologies used for existing nuclear power plants are dominated by light water reactors, which use water as a moderator and are divided into boiling water and pressurised water reactors. The boiling water reactor uses the reactor core with the fuel elements not only to absorb energy, but also directly for vaporisation at approx. 70 bar and approx. 280 °C. This has an advantage in terms of controlling the chain reaction: If too much heat is generated and therefore too much water is vaporised, the moderation performance drops and the number of nuclear fissions decreases. One disadvantage, however, is that radioactive particles from the core can be present in the steam, which can contaminate all components in the water-steam cycle. As a result, maintenance work on the turbine has to be carried out more carefully, which has a negative impact on maintenance costs.

There are two circuits in the pressurised water reactor, which are connected to each other by a heat exchanger, the evaporator. In the first circuit, which transports the heat from the reactor core to the steam generator, the water is under high pressure (approx. 160 bar), so that it can be used even at high temperatures. The gas does not vaporise at the high temperatures between 290 °C and 330 °C. Only in the second circuit is vapourised at 60 bar and 280 °C and can thus drive the turbine. Due to the low temperatures of the water vapour, the efficiency of light water reactors is quite low at around 35 %.

8 out of 10 countries with the largest share of nuclear power belong to the advanced economies, including France with 65% and the Slovak Republic with over 60%. In the USA, the nuclear share is only around 15 %, but with 94 nuclear reactors, it has the most in operation in the world. In the Emerging and Developing Economies (EMDE), nuclear energy already accounts for 5% of total electricity generation. Of these countries, Ukraine had the highest share of nuclear energy at around 50 % and Belarus the second highest at over 35 %.

Four other countries – Armenia, the United Arab Emirates, Russia and Pakistan – had a nuclear energy share of more than 10% in their electricity mix in 2023.

Grafik 3(siehe PDF-Dokument)

Russia and China are currently making the greatest efforts to build new nuclear power plants worldwide. Of the 52 reactor projects that have been started worldwide since 2017, 25 are of Chinese and 23 of Russian design (Fig. 3).

Grafik 4(siehe PDF-Dokument)

Half of the reactors under construction today are being built by Chinese manufacturers in China itself and outside China. China is on track to overtake the United States and the European Union in terms of installed nuclear power capacity by 2030.

Although the advanced economies hold two thirds of the world’s nuclear capacity, the vast majority of new builds are based on Chinese or Russian technology (Fig. 4).

In the European Union, the share of nuclear energy in the electricity mix peaked at 34% in the 1990s and has since fallen to 23%. In contrast, China is expected to more than triple its installed capacity by the middle of the century. In other newly industrialising and developing countries, it is expected to at least double.

Almost all countries and regions recognise the benefits of nuclear energy as a low-emission and controllable source of electricity that can make a valuable contribution to climate protection, energy security and the stability and reliability of electricity systems. This is reflected in recent political decisions to endeavour to extend the operating life of existing nuclear reactors: Upgrading projects to extend operating lives account for a large proportion of current investment in the nuclear sector (Fig. 5).

Grafik 5(siehe PDF-Dokument)

Decisions on lifetime extensions currently affect 64 reactors in 13 countries with a total capacity of around 65 GW. This affects around 15 % of the current global nuclear power plant fleet.

- In the USA, a total of 22 operators of operating reactors have applied for a lifetime extension.

- In Japan, reactors should be able to remain in operation for over 60 years.

- In France, the extension of the operation of 20 with a total installed capacity of 27.4 GW was confirmed.

- In Belgium, the Doel 4 and Tihange 3 nuclear reactors will remain online for longer.

- In Hungary, the operating times of the four units at the Paks nuclear power plant were extended.

- In the Czech Republic, the terms of Dukovany-3 and -4 were extended.

- Spain has stopped the nuclear phase-out and extended the operating life of its reactors.

- Finland has extended the operating times of units 1 and 2 of the Loviisa nuclear power plant and commissioned Europe’s largest nuclear power unit, Olkiluoto 3.

- In Romania, the operating life of unit 1 of the Cernavoda nuclear power plant is extended and two further units are reached.

- In the Netherlands, the service life of the existing plant in Borssele is to be extended and a further two units are to be added at the same location.

Innovation driver SMR

In addition to the extension of existing plants and the construction of new plants of the same technological generation, nuclear technology is already working on the introduction of next-generation plants. From the 1980s onwards, the initial focus was on standardisation in an attempt to reduce approval and construction costs. More recently, the idea of modular construction was added and the decision was made in favour of smaller output sizes in order to achieve a larger number of suitable applications.

This gave rise to the Small Modular Reactor as a generic term for a safe, reliable and economical system for generating electricity.

- “Small” refers to power sizes from 10 to around 300 MW reactors, which offer the advantages of long-term, cost-effective electricity production while minimising safety risks at a fraction of the size of the previous reactors. 1,300 MW power class.

- What “modular” has in common is that the Siemens/KWU idea of standardisation (the so-called Konvoi reactors) from the 1980s was adopted and a modular system was created as part of the further development of this idea. SMRs also consist of identical individual parts, which simplifies transport, certification and construction times.

The modularity and lower power class make the reactors interesting not only for the electricity industry but also for other branches of industry, as the demand from the private and industrial sectors for continuously available and climate-neutral energy is enormous.

There are a number of plans with varying degrees of maturity for future SMR use, which are primarily intended to cover the growing electricity demand of data centres. It is expected that a rollout of SMR by 2050 could contribute around 40 GW to satisfying the growing global hunger for electricity (2). This is not to be understood as an upper limit, as the SMR potential is far greater: according to a scenario in an IEA study (2, 4), which assumes favourable political support for SMRs, SMR capacity could even reach 120 GW by the middle of the century, with more than a thousand SMRs in operation by then. According to the IEA, this rapid growth scenario would increase investment in SMRs from less than USD 5 billion per year today to around USD 25 billion per year by 2030, resulting in cumulative investment of around USD 670 billion by 2050.

The specific construction costs of an SMR are still higher than those of a “normal” nuclear power plant built without exceeding the budget. This has to do with scale factors: a pump for twice the output costs less than twice the pump for the output. However, it is expected that there will be cost savings due to the modular design, which will materialise when the few prototypes are soon replaced by entire series. As soon as the specific construction costs for SMRs are reduced in this way over the next 15 years to those of large reactors built within budget, a 60 % increase in sales of SMRs is expected, which corresponds to a worldwide installed capacity of 190 GW by 2050.

The nuclear market could experience a renaissance with the introduction of the SMR. Interest in new construction projects has increased progressively in recent years (Fig. 6) (5).

Grafik 6(siehe PDF-Dokument)

The main advantage of SMR results from the reduction in the performance class. This has an effect on the preliminary costs, the development times of a specific realisation project and the construction risk.

Driven by the global demand for climate-friendly power generation, SMRs are a key focus of innovation in the nuclear industry. Several leading companies have made important technological advances in recent years. The first SMRs are expected to go into operation by the end of the 1920s.

The SMR power classes range between 10 MW and 470 MW. In addition, microreactor concepts (MMR) with an output of 1 to 10 MW are already under development.

The technical concepts are based on the processes of the successfully operated light water reactors, on those of the thorium high-temperature reactor THTR 300, which was developed in Jülich and tested as a prototype in Hamm, and also on completely new technologies.

Overall, SMR and MMR promise completely new applications. The IT sector in particular is showing great interest in SMR, as in some countries and regions data centres already account for a considerable proportion of electricity demand, leading to local grid and supply bottlenecks. In Ireland, for example, data centres consume 20% of electricity. In the US state of Virginia, the proportion is even more than 25%.

Technology companies are therefore increasingly looking for nuclear solutions to power their data centres. The demand for electricity from data centres will continue to rise enormously, as digitalisation and the increasing use of artificial intelligence are leading to major growth in this area. The expected output here is around 25 GW, with demand almost entirely localised in the USA.

Some other examples of SMR applications are

- Electricity and district heating supply for remote communities

- High-temperature process heat supply for trade and industry

- Power supply for data centres

- Seawater desalination

- Production of hydrogen

- Mobile traction power for ships and trains

- Drill holes

- Mining

There are currently more than 80 SMR concepts in the planning and prototype development stages. Some companies have already advanced their technologies to market maturity. Others are still in the early stages. Appendix A, Table 2, summarises the most important companies in the field of SMR, their technologies, prototype characteristics, development plans and already completed LOIs, procurement contracts and started or completed projects.

USA

In the USA, it is estimated that 200 additional nuclear reactors will be needed by 2050. The rapid growth of data centres there is expected to lead to an increase in electricity demand in the IT sector from the current 3% to 11% by 2030. Data centre customers expect climate-neutral services. For this reason, concepts with SMR are at the top of the list of possible options (6).

More and more data centres in the USA are planning a self-sufficient power supply with nuclear energy (Fig. 7). More and more of these are relying on SMRs. However, as these are not expected to be commercially available until the end of the current decade at the earliest, the recommissioning of decommissioned reactors is also being considered as an option to cover immediate requirements. The Three Miles Island accident reactor in Harrisburg is once again being discussed.

Nuclear power supplies for data centres are also increasingly being considered in India, Japan and Sweden. In recent years, it has become apparent that electricity customers now want to take matters into their own hands and support the development and construction of new nuclear projects instead of just purchasing nuclear power from the supplier or on the exchange.

Grafik 7(siehe PDF-Dokument)

A climate-friendly supply of data centres with photovoltaic and wind energy is inconceivable without enormous investment in storage. The planned annual reliability of data centres is 99.999%, which corresponds to a tolerated failure of 0.001% of the 8,760 hours per year or 5 minutes.

Their need for secure, uninterrupted and clean energy means that data centre operators are generally prepared to pay a premium for nuclear power. However, this is not necessary. Just as an in-house PV system produces the resident’s own electricity at twice the price of public generation and still becomes economical due to the elimination of grid costs, SMRs installed on the premises of data centres are already economical in almost all cases due to the elimination of grid costs.

Compared to wind and PV generation, this always leaves two economic advantages in favour of SMR: the elimination of grid costs only for SMR, as the required PV or wind power output cannot be generated on the company premises, and the elimination of storage systems, which have to smooth out the seasonal and daily progression of weather-dependent energies. Furthermore, in the case of weather-dependent energies, the part of the electricity that cannot be used spontaneously for the data centre or latently via the storage facilities themselves must be curtailed or sold at negative prices. This further increases the specific generation costs of weather-dependent power supply compared to those of SMR power generation.

Europe

McKinsey (7) expects demand for power from data centres in Europe to increase by 25 GW to around 35 GW by 2030, which corresponds to 5% of total demand. This is seen as the most important short-term growth driver for Europe’s demand for electricity.

France announced an investment programme to invest EUR 109 billion in the construction of data centres and technical infrastructure over the next five years. The electricity is to come from nuclear power plants and renewable sources. France therefore appears to be in a much better position than Germany in terms of power supply for data centres.

As in France, electricity for data centres in most other EU countries is mainly generated from renewable energy sources, which are defined differently depending on the individual country. The challenge appears all the greater as a large part of the transport and logistics, building energy, process industry and other sectors are to be decarbonised at the same time. The energy required for reliable 24/7 availability — the controllability of generation plants required for “green” electricity — is only possible for pumped storage and dam hydropower, but only to a very limited extent and can only be met for a few hours. Run-of-river power plants, wind turbines and photovoltaic systems can only be curtailed, which means that the available flow or irradiation is not used to generate electricity. They cannot be ramped up to full load during weather-related partial loads.

Whether you need base load capability or not is debatable. But you do need a stable grid with a reliable, controllable feed-in. SMRs can make a contribution to stabilisation. Within Europe, Germany in particular is facing major challenges after the country phased out nuclear energy in 2023 and, like Spain, is relying on a generation structure with very high volatile shares.

The causes of the nationwide blackout in Spain on 28 April 2025 have not yet been conclusively clarified. The hypothesis that the inverters of a large number of large PV parks simultaneously triggered a disconnection when the grid frequency exceeded 52 Hz, resulting in a shortage that caused the grid to fail, appears to be realistic. The cause of the increase in grid frequency is said to have been feed-in surpluses from PV systems.

The Spanish blackout could have been avoided with more stabilising rotating masses of turbines and generators from larger power plants and better feed-in control.

Worldwide Forecasts

The IEA (2) forecasts that global investment in nuclear energy and installed capacity will rise sharply. The forecasts were analysed in 3 scenarios (14). It is currently assumed that cumulative investment in nuclear energy will increase to between USD 1.7 trillion and USD 2.9 trillion in the period up to 2050. Large reactors will account for the largest share, with the share of SMRs (currently at 0 %) expected to be between 17 and 33 per cent (Fig. 8).

Grafik 8(siehe PDF-Dokument)

The IEA scenarios illustrate different paths that the energy sector could take, the levers that decision-makers can use to achieve them, and their implications for energy markets, security and emissions:

- The Stated Policies Scenario (STEPS) is an exploratory scenario that analyses today’s policy framework based on a sectoral and country-specific assessment of the energy-related policies in force at the end of August 2024 and those currently being developed. The scenario also takes into account the currently planned production capacities for clean energy technologies.

- The Announced Pledges Scenario (APS) is an exploratory scenario that assumes that all climate pledges made by governments and industries worldwide by the end of August 2024 (including Nationally Determined Contributions (NDCs) and longer-term net zero targets), as well as targets for access to electricity and clean cooking, are met in full and on time.

- “Net Zero Emissions by 2050” (NZE) is normative and shows a pathway for the global energy sector to achieve net zero carbon dioxide (CO2) emissions by 2050. It does not rely on emission reductions outside the energy sector to achieve its target. Universal access to electricity and clean cooking are achieved by 2030. The scenario was updated with the latest data in 2024.

Grafik 9(siehe PDF-Dokument)

The increasing development activities and the expected wave of new builds in the countries of origin of nuclear energy could lead to these countries – in particular the USA, France and the UK – returning to the “driver’s seat” (Figs. 9 and 10).

Grafik 10(siehe PDF-Dokument)

Technology of the SMR

Classification

What all SMRs have in common is that they are modular nuclear fission reactors that are smaller than conventional reactors.

- The term “small” refers to the power range (up to less than 10 MWe (microreactors) and typically up to 300 MWe).

- The term “modular” refers to the design principle that uses standardised subsystems.

- The term “reactor” refers to the nuclear reaction to provide heat for the energy conversion process.

The classification distinguishes between previous “conventional” technologies of light water reactors and the advanced technologies of the next generation. The nuclear fuel used (uranium, thorium or other), the moderator used (water, graphite or other), the coolant used (light or heavy water, liquid metal, liquid salt, helium or other) and the number of circuits (one, two, three or more) are used as subgroups of advanced SMRs as a distinguishing feature.

Grafik 11(siehe PDF-Dokument)

Conventional SMR

SMR types with conventional technology

The existing SMRs are based on the use of uranium as a nuclear fuel and the use of (light) water as a coolant and moderator. These are light water reactors (LWR):

- LWR: An LWR is a nuclear reactor in which so-called light water – as opposed to water with deuterium isotopes – is used as a coolant and moderator. There are two basic types of light water reactor, the boiling water reactor (BWR) and the pressurised water reactor (PWR).

- BWR (boiling water reactor): The heat generated during nuclear fission vaporises water (boiling water cooling) at e.g. 71 bar and 286 °C in the reactor pressure vessel; the steam is fed directly to the turbine and drives it. The worldwide distribution of BWRs of all sizes is around 50 units.

- PWR (pressurised water reactor): In the pressurised water reactor, two water circuits transport the heat generated during nuclear fission to the turbine. In contrast to the BWR, the operating pressure (approx. 160 bar) of the water in the primary circuit, which flows through the reactor core to the steam generator, is set so high that it does not boil at the intended operating temperature. The fuel rods are therefore evenly wetted, the heat distribution on their surface is balanced and the vapour phase with its particular corrosive effect is eliminated. The water from the primary circuit heated in the reactor core transfers its heat to a separate water-steam circuit, the secondary circuit, in a steam generator. The secondary circuit is free of radioactivity from abrasion and corrosion products, which makes it much easier to maintain the steam turbine, for example. The worldwide distribution of PWRs of all sizes is around 300 units.

Excursus: Since the water not only acts as a coolant but also as a moderator, the BWR has its own inherently safe shutdown: If the temperature rises and more water evaporates than intended, the moderating effect of the water decreases, which means that fewer thermal neutrons are available for fission. This reduces the power output. In the 1980s, this principle led to the development of self-regulating reactors based on the BWR with a natural circulation. At that time, however, there were no interested customers, so this concept was not further developed.

Special properties

SMRs are characterised by their power range (10 – 300 MW) and their modularity. Features:

- Simple design, modular, greater flexibility

- Cost-saving, flexible in terms of installation locations, transportable

The first SMR reactors were developed back in the 1950s for various applications. These included mobile applications as propulsion for ships and especially for submarines. The advantage of military use in submarines was the long silent immersion times that could be achieved, as no atmospheric oxygen was required for combustion and no exhaust gases had to be discharged.

The submarine reactors were godfathers for the development of larger plants used on land, such as the Würgassen (SWR) and Stade (DWR) nuclear power plants, the first two larger power reactors in Germany with 670 MW each. Later nuclear power plants in Germany corresponded to the 1,300 MW unit size.

Grafik 12(siehe PDF-Dokument)

SMRs were rediscovered in the course of the climate debate.

There are currently around 80 different SMR projects worldwide that correspond to small conventional LWR reactors.

In addition to the classic application for public power supply (control and reserve energy as well as stabilising rotating masses and protection against dark periods), many new applications are opening up for SMRs:

- Process heat supply for trade and industry

- Power supply for data centres or the aluminium and copper industry

- Power supply for regions that are not connected to a grid

- Seawater desalination

- Electrolytic production of hydrogen

Advantages of conventional SMR

- Less capital tied up: SMR reactors can be adapted to the actual power requirement and can therefore be used without oversizing. There is no need to market capacities that you do not need yourself. The initial investment corresponds to the company’s own energy requirements. The industrial investor does not become an energy supplier for third parties.

- Cost degression through quantities: The modular design and the small power classes make it possible to produce a larger number of identical SMRs. This has an effect on the specific manufacturing costs.

- Authorisation procedure: Plant safety, the safety of plant operation, the potential impact on the environment and the neighbourhood as well as the dangers of the fuel path from the mine to disposal and also the demolition of the plant itself and its disposal can be assessed for the first prototypes. The expert reports are available 1:1 for the approval procedures of all subsequent projects. Only the individual meteorological conditions have to be prepared in individual reports on the immission forecast for specific locations.

- Prefabricated construction: The small sizes and modularisation mean that many components can be manufactured in the production plant instead of on the construction site. This significantly reduces the assembly time on the construction site.

- Site utilisation: SMRs can be operated at all sites where conventional nuclear power plants or coal-fired power plants were previously located. They can utilise the existing grid feed-in points and can be equipped with dry cooling towers to be independent of river water so that 100% output can be generated even in hot and low water conditions.

Technology of advanced SMR concepts

Development of Generation IV reactors

In addition to conventional SMRs based on PWR and BWR technology, there is now a subgroup of advanced Advanced Small Modular Reactors (ASMRs) developed as part of the Generation IV programme.

Generation IV nuclear power plants were developed to fulfil more stringent requirements in terms of safety, sustainability and economic efficiency.

- Operability without active intervention by operating personnel or control technology leads to inherent safety

- Fuel management without the possibility of diverting fissile material avoids the military usability of the operating materials used in the plants

- Dispensing with uranium enrichment avoids the handling of militarily usable isotopes

- Improving security against terrorist attacks is effective as self-protection and civil defence

- Fuel recycling with reuse of radioactive residues as fuel leads to minimisation of repository quantities

- Reduction in operating costs reduces life cycle costs compared to other forms of energy

With the aim of jointly developing the fourth generation of nuclear reactors, a large number of countries came together in 2001 to form the Generation IV International Forum (GIF).

Molten Salt Reactor (MSR)

The MSR is an advanced reactor in which liquid salt is used as the coolant for the primary cooling circuit and which is being developed as part of the Generation IV programme. Compared to the light water reactors described above, the MSR has additional special features with regard to preventing a core meltdown.

The MSR typically consists of 3 circuits:

- In the first circuit, the primary circuit, a liquid mixture of nuclear fuel and molten salt circulates at a temperature of 700 °C. It transfers the heat released during the nuclear physical process to the second circuit via a first heat exchanger. The nuclear fuel melted as intended is evenly distributed in liquid form in the primary circuit of the reactor. Due to the “liquid” aggregate state selected for the design, no unwanted core melt can occur. As the primary circuit also operates under atmospheric pressure, an explosion is also ruled out. In addition, the components are thin-walled due to the low pressure, which means that a lightweight design can be realised that makes the reactor usable for aerospace applications.

- In the variant shown, a heat transport circuit is connected to the primary circuit, which connects the first circuit with the third circuit. This circuit is single-phase liquid and is therefore pressurised.

- The actual water-steam cycle is designed as a third cycle. Due to the high temperatures of the MSR, efficiencies can be achieved that are higher than those of today’s state-of-the-art coal-fired power plants.

The fuels used in the MSR can be uranium, plutonium or thorium, depending on the concept. Depending on the design, fast neutrons can be used for incubation (fast MSR or MSFR) and thermal neutrons, which are slowed down by a moderator, can be used for fission only. It is possible to integrate an inherent protection that reduces the chain reaction rate or even stops the reaction completely if the power increases contrary to the intended schedule.

Excursus: One example of a thorium MSR is the MSR from the Danish start-up Copenhagen Atomics (11). Here, heavy water is used as a moderator. Thorium-fissile U233 is produced using thermal neutrons (thermal breeder). This type of reactor has great potential because the world’s thorium reserves are three times greater than those of uranium.

Grafik 13(siehe PDF-Dokument)

Special features of the MSR:

- The risk of hydrogen explosions (as in Fukushima) can be ruled out.

- The gaseous fission products (e.g. Xe and Kr) can be easily captured when they are released or blown out of the fuel.

- MSR fuels can be topped up during power operation (conventional reactors must be switched off for topping up).

- The operating temperatures of MSRs are around 700 °C and therefore significantly higher than those of conventional PWRs (300 °C). This increases the efficiency of power generation and enables the utilisation of MSR to generate high-temperature process heat.

- The atmospheric pressure in the primary circuit is lower than the 160 bar in a pressurised water reactor, which offers major advantages in terms of safety. The probability as well as the possible effects of an accidental major rupture with loss of coolant are significantly lower.

- Less highly radioactive waste is produced during operation of the MSR.

The MSR was developed back in the 1960s at Oak Ridge National Laboratories. Today, many development teams rely on this technology. In particular the corrosion problems arising from the use of salt are at the centre of further development. In addition, safety properties are also being improved and measures are being taken to increase economic efficiency.

The MSR can be used to achieve a very long travelling time with a low use of nuclear fuel precisely because of its basic characteristic of usability as a breeder reactor:

- Breeding nuclear fuel by bombarding it with fast neutrons extends fuel utilisation times and increases the efficiency of the fuel.

- The fission products can be incubated into isotopes with significantly lower toxicity and/or significantly shorter half-lives.

- Spent fuel elements from conventional nuclear power plants can be reprocessed and used in the SMR. This reduces fuel consumption and the repository volume.

Most work is currently focussed on the MSFR. China seems to favour this technology.

Excursus on fast reactors: Of the uranium isotopes present in nature, only uranium-235 (0.7 %) can be split in the LWR. However, the process can be controlled in a special type of reactor so that uranium-238 (99.3 %) is also utilised. Uranium-238 absorbs a neutron and uranium-239 is produced, which is converted into fissile plutonium-239 via neptunium-239. This process allows more fissile material to be produced than is consumed by nuclear fission for reactor operation. As fast neutrons are used for the process in such a reactor, this type of reactor is also known as a “fast breeder”. As such reactors are only operated with fast neutrons, there must be no moderator. Water is therefore unsuitable as a coolant, as it slows down (moderates) the neutrons to low speeds. Liquid sodium or liquid lead, for example, is therefore used as a coolant.

Liquid Metal Reactor (LMR)

LMRs (liquid metal reactors) use liquid metals as coolant. Liquid metals have a very high heat capacity and also very good thermal conductivity. This is the reason why an LMR has a particularly high power density. Liquid metals such as sodium or lead have no moderating effect that could be used to slow down the fast neutrons produced during nuclear fission to the energy level of thermal neutrons required for the fission of uranium. For this reason, LMRs are generally designed as fast breeder reactors.

The advantages mentioned above for the MSFR also apply here:

- Long fuel cycles ensure that the fuel inventory is fully utilised.

- A reduction in the number and radiotoxicity of fission products is achieved by bombardment with fast neutrons.

LMRs are used both to generate electricity and to breed new fissile material. In principle, the breeding process with fast neutrons makes it possible to utilise natural uranium around sixty times better than in a light water reactor with thermal neutrons. LMRs alleviate the problem of final disposal by absorbing fast neutrons in fission products.

Dual Fluid Reactor (DFR)

The DFR combines the advantages of the molten salt reactor with those of metal-cooled reactors. It is a breeder reactor that operates with fast neutrons and has a primary lead and a secondary water-steam cycle.

As with the MSFR, in which the first circuit consists of a mixture of liquid nuclear fuel and liquid salt, the heat is generated by fission processes in the reactor core. In contrast to the MSFR, however, this mixture does not circulate as a circuit between heat generation in the core and heat dissipation in the heat exchanger, but remains in the core, which itself is equipped with pipes for the first cooling circuit like a heat exchanger.

The heat from the splitting and incubation processes is absorbed by the lead and transferred to a second heat exchanger. Here, the water from the water-steam cycle is vaporised and superheated before being fed to the turbine.

With the DFR concept, all the aforementioned advantages of the LMFR can be realised. The particularly compact reactor was designed in Germany and is currently undergoing further development in Canada.

Grafik 14(siehe PDF-Dokument)

High temperature reactor (HTR)

HTRs are nuclear reactors that enable significantly higher operating temperatures than other known reactor types (14), which is particularly advantageous for the provision of high-temperature process heat. For this purpose, the coolant must be gaseous. In the prototype of the HTR, the THTR 300 thorium high-temperature reactor developed at the Jülich nuclear research facility and built in Hamm Uentrup, helium was chosen as the coolant.

In addition to the gaseous coolant, ceramic instead of metallic materials are also used in the reactor core for temperature reasons. As in the world’s first nuclear reactor built by Fermi, Chicago Pile 1, the moderator is graphite. In the HTR, the core consists of graphite spheres the size of tennis balls, into which small particles of uranium or thorium ceramics are baked as fuel. The fuel and moderator are therefore inseparable. As the temperature of the fuel-moderator spheres increases, the effective cross-section for the chain reaction changes and the power output decreases. This makes the process inherently safe. For a quick shutdown, there is a quick ball release with which the fuel moderator balls are removed from the core via gravity mechanisms. The THTR 300 prototype in Hamm Uentrop had problems with this rapid shutdown, which is why the research project was cancelled. This decision is controversial.

As already described, the heat generated during fission is absorbed by the helium, which heats up to approx. 1,000 °C in the process. It becomes a turbine which converts the pressure resulting from the heat absorption into rotational energy with which the generator is operated.

After the concept was abandoned in Germany, China adopted the technology and has been operating a 300 MW test reactor since 2003.

Due to the high helium temperatures, the THTR has a particularly high level of efficiency. The large amount of heat can also be used as process heat to produce hydrogen or refine coal.

Grafik 15(siehe PDF-Dokument)

New areas of application for SMR

The provision of process steam for the chemical and pharmaceutical industries

The decarbonisation of all processes reaches its limits when using heat pumps; the greater the required temperature range between the heat source and the application, the more electrical energy is required to raise the temperatures. The heat pump is the reverse of the power plant process. Whereas in a power station, mechanical energy is generated from high temperatures in the steam generator in the turbine, which turns the generator that produces electricity, in a heat pump an electric motor turns the compressor, which generates the pressure difference that causes the circulating medium to vaporise at low (ambient) temperatures and condense again at high (heat sink) temperatures (Fig. 15).

The direct use of process steam from nuclear reactors at a high temperature level is an opportunity for the chemical and pharmaceutical industry to decarbonise economically.

Grafik 16(siehe PDF-Dokument)

Excursus: While the aim in power stations is to achieve the greatest possible temperature difference between the superheated steam and the condenser vacuum in order to generate as much electricity as possible with a high degree of efficiency, the opposite is true in the heat pump process: the higher the desired process temperature and the lower the heat source temperature, the more electrical energy must be used for the compressor. When raising the temperature from 10 °C to 40 °C, as required for heating purposes in the building energy sector, around 1/3 of the electrical energy is needed to bring environmental heat up to the useful heat level. At 100 °C, this is already around 50 per cent. The process temperatures in chemical production plants are much higher and require 500 °C and more. Here, the proportion of electrical energy in the heat provided is already well over 70 per cent. Another problem with high-temperature heat pumps is the material suitability of the components and seals. Even above 100 °C, it becomes difficult to find suitable components.

The decarbonisation of high-temperature processes must be achieved either directly with 100 per cent electrical energy or with process steam from nuclear power plants, otherwise fossil fuels must continue to be used. This is an area of application that the developer of the thorium high-temperature reactor THTR, Prof. Rudolf Schulten, had in mind when he designed the THTR 300 as a prototype. Even though this first reactor was a technical and certainly not a commercial success, it was the inspiration for the development of the SMR.

Use of SMR for the production of hydrogen

Another possible application for SMRs is the production of hydrogen. Due to the high investment costs of electrolysers, they should be utilised continuously with more than 7,000 full-load hours per year if possible. Operation by a wind turbine (WT), which achieves around 2,000 to 2,500 full-load hours onshore, is not very economical, as the volatility reduces the durability of the electrolysis. Bundling wind turbines located in different regions increases the joint number of full-load hours, but makes it necessary to use the transport and/or distribution grid for the electricity, which in turn increases the costs.

For this reason, electrolysis plants for the production of hydrogen should be located on the site of a base load power plant wherever possible. The hydrogen, in turn, can be utilised to compensate for reduced loads in the grid by being expanded in a gas turbine. This would result in a sensible symbiosis of SMR, electrolysis, hydrogen tanks and hydrogen-fuelled gas turbines.

At temperatures of around 3,000 °C, it is possible to split water directly into hydrogen and oxygen. Provided the temperatures can be controlled on an industrial scale, it could therefore be possible to split water directly in the future using heat from SMRs.

Other aspects

Disposal of spent fuel elements

The topic of nuclear waste disposal has already been dealt with in detail in the GES basic documentation (1). With regard to the SMR, the following aspects still need to be considered.

Reduction of the radioactivity of fission products

MSFRs and DFRs and LMRs can be designed as breeders. The primary use is the own production of fuel. The bombardment of fission products from the reactor process and possibly also the bombardment of spent nuclear fuel from other nuclear reactors can be used to breed the isotopes produced during fission and thus either achieve shorter half-lives for radioactive decay or even make them stable directly by absorbing a neutron.

Reprocessing

Another option for mitigating the problem of radioactive waste is reprocessing. In Germany, the project for a reprocessing plant in Wackersdorf (WA 350) was abandoned at an early stage as a result of public protest. Various countries, such as France and the UK, operate reprocessing plants. In a reprocessing plant, uranium and plutonium, for example, are extracted from the fuel rods (PUREX process). MOX (mixed oxide) fuel is produced from this. This also reduces the volume of radioactive waste.

Excursus: After reprocessing, the highly radioactive waste can only take up around 20 % of its original volume. After about 30 years, the heat release of the reprocessed waste has fallen by about 70 %.

Waste from German nuclear reactors is only vitrified in a reprocessing plant so that it cannot later be retrieved and transported to a final repository. This is regulated in the German Atomic Energy Act.

The search for a final repository for highly radioactive nuclear waste is proving difficult in most countries. Burying it underground is meeting with resistance from the population.

Grafik 17(siehe PDF-Dokument)

Reactors that work on the basis of fast neutrons can also be used to “incinerate” radioactive waste, as explained above. All existing residues that are currently stored above ground in CASTOR casks are suitable for this purpose (35, 36). With SMFR, a large part of the material intended for final disposal and its longevity could be significantly reduced, for several reasons: 100,000 years would be several hundred years, so that near-surface disposal would be sufficient. For decay curves of the radiotoxicity of nuclear waste, see Fig. 16.

Repository

The issue of final storage has been resolved differently in the various countries in which nuclear power plants are operated. For all countries, however, the spent nuclear fuel must be stored in the country where the power plant was located that produced the residues during operation.

- According to the Repository Search Act, the site for a repository for highly radioactive waste is to be found within Germany – with an open outcome, transparently, according to legally defined technical criteria and with public participation. It is not enough for the legally prescribed selection process to find a suitable site for a repository. The site to be selected must also be demonstrably the best of all possible sites in Germany. This criterion makes it impossible to determine a site, as it is not possible to prove the superlative in the assessment.

- The site is to be finalised by 2031 and the repository is to be commissioned by 2050. The politicians of the government in office at the time of the decisions will find reasons for a postponement.

- From today’s perspective, no reprocessing is planned. The same applies to possible transmutation.

- The retrievability of the waste is required internationally. This is also a consequence of the necessary clearance of the Asse repository for medium-active residues from medical and industrial use and, in part, also from nuclear energy.

It can be assumed that the search for a final repository and the shipment of radioactive waste will continue at least until after 2100 (18).

Transmutation

Another method of reducing the radioactivity of nuclear waste is transmutation. Here, fission products are bombarded with fast neutrons from neutron sources. This causes the fission products to be incubated or further fissioned until new isotopes are produced, which either decay very quickly or are already stable. Development projects for transmutation exist, for example, in France, Belgium, the UK, the USA and Canada. The Swiss/German company Transmutex is also developing such a system (19).

Transmutation could significantly reduce the radiation intensity of nuclear waste and the duration of radiation. Based on the results of Transmutex to date, the following predictions can be made:

- The volume of the most radioactive waste is reduced by a factor of 8.8.

- The required containment period can be reduced from 1 million to 830 years.

Transmutation itself is in line with the existing legal framework. However, the use of highly radioactive waste in transmutation facilities requires changes to the law.

If the development of transmutation leads to success, the final storage issue would solve itself. The US Department of Energy has already defined the Transmutex process as a reference technology for the reduction of radioactive waste (20,21).

Safety

Supervision of the safety of nuclear reactors is the responsibility of the competent national and supranational authorities. A detailed description for Germany (22) and Europe (23) can be found on the Internet. The corresponding regulations for large nuclear power plants initially also apply unchanged to SMRs. As these have so far only existed as prototypes, it is to be expected that the regulations will be modified and supplemented with increasing experience, as it is not yet possible to make any statistical statements on the safety of SMRs based on operating experience.

However, an extrapolation of the results obtained with existing systems and via tests and calculations to SMR already allows the following conclusions to be drawn:

- SMRs have a higher level of safety due to their smaller power size and lower radioactive inventory.

- MSRs in particular have inherent safety and a lower integrity risk due to the lower operating pressure.

- HTRs also have inherent safety.

- MSFRs, LMRs and DFRs working with fast neutrons have the advantage of breeding processes and integrated transmutation of the fission products, which alleviates the problem of final disposal.

For risk aspects, please refer to the further literature (24, 25).

SMR utilisation in various regions

Germany

The current status of analyses of the potential of SMRs by the Federal Office for Safety and Nuclear Waste Management (BASE) is disappointing. BASE does not recognise any advantages of SMRs over conventional reactors in terms of costs and safety (26).

The new federal government is likely to change this. Research into future topics relating to nuclear technology has been expressly included in the coalition agreement. Research without the will to realise positive results must not be supported with taxpayers’ money. Conversely, it follows that Germany is preparing for the construction of SMR prototypes.

European Union

The EU Commission has already established a dedicated programme for the development of novel reactor technologies in February 2024: “European industrial alliance on SMR”. The EU-SMR industrial alliance will focus on accelerating the deployment of these reactor types and ensuring a strong EU supply chain, including a skilled workforce.

The alliance will focus on the following key areas:

- Identify the most promising, advanced, safe and cost-effective SMR technologies eligible for Alliance support

- Supporting SMR projects, strengthening the European supply chain (including fuels and raw materials) by eliminating potential gaps and advising SMR projects from inception to implementation

- Identifying investment barriers, analysing financing options and exploring new financial mix options for SMR development

- Find ways to inform and involve potential industrial users of SMR such as energy-intensive industries, hydrogen producers, etc.

- Identification of future research needs in the field of nuclear reactors and advanced modular reactors (AMR), identification of skills gaps along the supply chain that could be addressed by the Euratom research and training programme and national programmes

- Intensifying exchanges and contacts between project organisers, European nuclear safety regulators and regulatory authorities in EU countries

- Promoting public engagement on nuclear energy through cooperation with relevant civil society organisations and NGOs

- Facilitate the establishment of a Nuclear Skills Academy and identify future skills and qualification development needs

- Co-operation with relevant international bodies to support European SMR projects in international markets

The Euratom Research and Training Work Programme 2023-2025 has a budget of EUR 132 million, of which EUR 15 million is earmarked to support the safety of European light water SMRs and EUR 12 million to co-fund researchers and industry to work together on the safety of advanced modular reactors, including SMRs.

The SMR Alliance emphasises that by expanding cooperation at EU level, the Alliance will accelerate the introduction of the first SMRs in the EU by the early 2030s. This will be done in compliance with the highest nuclear safety standards.

The Alliance has selected initial projects for working groups. These working groups will investigate the realisation of various SMR concepts. Some of these concepts can already be found in the appendix, which lists the global SMR projects that are already in the realisation phase:

- EU-SMR-LFR project (Ansaldo Nucleare, SCK-CEN, ENEA, RATEN)

- CityHeat project (Calogena, Steady Energy)

- Project Quantum (Last Energy)

- European LFR-AS project (Newcleo)

- Nuward (EDF)

- European BWRX-300 SMR (OSGE)

- Rolls-Royce SMR (Rolls-Royce SMR Ltd)

- NuScale VOYGR SMR (RoPower Nuclear SA)

- Thorizon One Project (Thorizon)

The first meeting of the SMR Alliance was attended by 14 countries. Germany did not take part and did not send an observer.

USA

The US government assumes that an additional 1,500 to 2,000 GW of climate-neutral generation capacity will be required by 2050. In addition to renewable energies, nuclear energy (both SMRs and micro and large reactors) will play a key role in this. Several initiatives to promote these technologies have been set up or are being supported by the government.

In addition, the Inflation Reduction Act (IRA) programme created new incentives for the nuclear industry in September 2022, including tax breaks and simplified lending. The Advance Act, which came into force in July 2024 and sets out the requirements that must be met in order to accelerate the deployment of nuclear energy technologies (including advanced reactors), is aimed in a similar direction.

Costs of SMR

The investment costs (CAPEX) and operating costs (OPEX) for an SMR can only be estimated with great uncertainty from today’s perspective due to a lack of concrete project experience. However, it can be stated that the following features offer great potential to significantly reduce the costs of SMRs compared to conventional nuclear power plants with a capacity of 1 – 2 GW:

- Identical construction of modules

- Elimination of location-specific features

- High scaling potential

- Industrial production in centralised plants

- Simplification of authorisation procedures

A report by Elsevier (30) “Economic potential and barriers of small modular reactors in Europe”, which is based on a systematic review and evaluation of the relevant specialist literature, comes to the following conclusion:

- The average capital costs per kW for SMRs are estimated at approx. 7,000 €/kW. They are therefore around 40 % higher than for large reactors.

- The electricity generation costs of SMR are estimated at €0.08 to €0.09/KWh. This is only slightly higher than the feed-in tariff for PV electricity from private rooftop systems. It is in the order of magnitude of today’s industrial electricity prices.

- A cost degression can be assumed as part of the further development.

Sources

(1) BMZ-report, Title 687 01

(2) IEA “The road to a new era of nuclear energy” 10/2024

(3) Definition of advanced economies: www.imf.org/en/Publications/WEO/weo-database/2023/April/groups-and-aggregates

(4) IEA scenarios

(5) www-pub.iaea.org/MTCD/Publications/PDF/p15790-PUB9062_web.pdf

(6) McKinsey: How data centres and the energy sector can sate AI’s hunger for power

(7) www.mckinsey.com/industries/electric-power-and-natural-gas/our-insights/the-role-of-power-in-unlocking-the-european-ai-revolution

(8) www.iaea.org/newscenter/news/what-are-small-modular-reactors-smrs

(9) www.motive-power.com/visualized-the-four-benefits-of-small-modular-reactors/

(10) Wikipedia “Molten Salt Reactor”

(11) www.copenhagenatomics.com

(12) Wikipedia “Dual Fluid Reactor”

(13) www.dual-fluid.com

(14) Wikipedia High-temperature reactor

(15) Werner Schnurberger “Water splitting with electricity and heat”

(16) Wikipedia Reprocessing

(17) Nuklearia, Rainer Klute, https://nuklearia.de/

(19) www.zeit.de/wissen/2024-08/atommuell-endlager-suche-steffi-lemke-faq

(20) www.transmutex.com

(21) www.nuklearforum.ch/de/news/transmutex-erzielt-wichtige-fortschritte-den-usa-and-germany/

(22) www.nuklearesicherheit.de

(23) www.nuklearesicherheit.de/europa-und-internationales/

(24) www.base.bund.de/de/nukleare-sicherheit/kerntechnik/alternative-reactorconcepts/alternative-reactor-concepts_content.html

(25) www.sprind.org/worte/magazin/sprind-und-transmutex

(26) www.base.bund.de/de/nukleare-sicherheit/kerntechnik/alternative-reactorconcepts/alternative-reactor-concepts_content.html

(27) https://energy.ec.europa.eu/news/commission-ally-industry-small-modular-reactors-2024-02-09_en

(28) www.nucleareurope.eu/press-release/commission-launches-european-industrial-alliance-on-smrs/

(29) US political framework (world Nuclear news)

(30) www.sciencedirect.com/science/article/abs/pii/S1364032124004696

(31) www.nuklearforum.ch/de/news/grossbritannien-sechs-anbieter-fuer-nationalen-smr-selected/ (Swiss Nuclear Forum)

(32) www.world-nuclear-news.org/articles/reactor-internals-in-place-at-chinese-smr

(33) www.nuklearforum.ch/de/news/russland-baut-kleines-kernkraftwerk-aus-sechs-smrs-usbekistan/

(34) www.grs.de/en/nuclear-energy-russia-16082023

(35) Leidinger, B.J.G.: Design of an air-cooled transition store for fuel elements from nuclear power plants. (VDI-Fortschritt-Berichte. Reihe 6: Energietechnik/Wärmetechnik. Nr. 177), 1985.

(36) Leidinger, B.J.G.: Economical Dry Storage of Large Amounts of Spent Fuel and Vitrified High Level Radioactive Waste, OECD-NEA Specialist Workshop on Dry Storage of Spent Fuel Elements, Madrid, pp. 79/87, May 1982

List of abbreviations

- NPP – Nuclear power plants

- LWR – Light water reactors

- PWR – Pressurised water reactor

- SWR – Boiling water reactor

- SMR – Small Modular Reactor

- MSR – Molten Salt Reactor

- MSFR – Molten Salt fast Reactor

- FMR – Liquid Metal Reactor

- DFR – Dual Fluid Reactor

- HTR – High Temperature Reactor

- IEA – International Energy Agency

- EMDE – emerging market and developing economies

- GB – Great Britain

- HUB – Node (e.g. for computers)

Appendix: Overview of the most important SMR projects worldwide

Region / Country / The company / Owner / Designation / Operating principle / Module output (MW)

North America, USA: NuScale Power — VOYGR-6 — PWR — 77

North America, USA: Westinghouse — AP300 — PWR — 300

North America, USA: GE Hitachi Nuclear — BWRX-300 SMR — BWR — 300

North America, USA: Terrapower (Gates Foundation) — LMR, Na — 345

North America, USA: X-Energy — Amazon — gas-cooled — 320

North America, USA: Kairos Power — Google — MSR, uranium/ceramic — 140

North America, USA: Holtec — Holtec — PWR — 160

North America, USA: Oklo — Dunedin/Canada — MSR (utilisation burnt fuel)

Canada: MoltexEnergy — (see appendix)

Asia, China: CNNC — APC100 — PWR — 125

Asia, Korea: KHNP — iSMR — PWR — 170

Europe, GB: Rolls-Royce SMR — PWR — 470

Europe, F: Nuward (EDF) — PWR — 200–400

Europe, I/F: Newcleo — LMR Lead cooling — 30, 200

Russia/Uzbekistan: Rosatom — RITM-200N — LWR, lead — 200

Russia: Rosatom — Brest 300 — LMR Lead — 300

Russia: Rosatom — RITM-200N variants — LWR — 200

Comments on appendix:

1) Based on the number of projects, the number of different designs, the financial resources available and the target realisation dates, the USA is clearly the world leader in SMR development and use.

2) The British government organised a competition in 2023 to select the best SMR for the UK and promote its development. 6 manufacturers made it through to the next round: EDF, GE-Hitachi, Holtec Britain, NuScale Power, Rolls Royce SMR and Westinghouse (31).

3) China (26): The target commissioning date for the Chinese SMR is 2026. This would put China at the top of the timeline!

4) Russia probably has the longest experience with SMR. This covers many different areas of application: Energy supply, supplying cities, heat supply, transport on ships, icebreakers, etc. It would be desirable if Russia, after the current ice age, were to use its broad experience to participate in the international exchange of information again soon. It is not apparent that Russia is aiming to participate in international competition for data centres. Russia is probably focussing on applications for EMDE countries. With its good relations there, Russia is well prepared. Russia is also very active abroad: Egypt, Bangladesh, Belarus, China, India, Turkey and Hungary (32,33).

Explanations of the various projects (selection):

[1] LOIs or agreements with Bulgaria, Canada, the Czech Republic, Ghana, Indonesia, Korea, Poland, Ukraine and the United States. A 462 MW SMR power plant with six modules is planned in Romania. In the UK selection process among the last 6. In 2024, NuScale abandoned its SMR plans. However, NuScale is still in business.

[2] Was shortlisted for the SMR selection process in the UK. The first unit is to be built in the early 30s. Westinghouse signed agreements with Canada, the Czech Republic, Romania and Ukraine.

[3] The first BWR 300 is to go to Ontario Power Generation. 3 more in planning. Construction to start in 2024, commissioning in 2029. Is also in the 1st stage of the GB competition. LOIs with the Czech Republic, Estonia, Poland and Sweden. Poland is planning 79 SMRs with GE Hitachi.

[4] Commissioning 2030.

[5] First reactor in Texas, commissioning in 2029, 3 more planned in Washington. Up to 5 GW planned in the USA by 2039. Pre-licensing for projects in Canada completed. Agreement with local energy supplier Dominion Energy.

[6] Google has ordered 7 SMRs. The first SMR should be operational by 2027. 500 MW by 2035.

[7] In the GB selection process among the last 6. co-operation partner Hyundai.

[8] Completion planned by 2027. 2 further reactors in the planning stage.

[9] LOI for SMR construction in Canada, operational in the early 1930s.

[10] Start of construction in 2021, commissioning in 2026, could be the first commissioning of an SMR worldwide (32).

[11] Target: Design approval 2028.

[12] Selected as preferred supplier in the Czech Republic. Start of construction in 2025. LOIs with Sweden, Poland. First MSR in the UK in the early 30s. Cooperation with Siemens Energy for turbines.

[13] Construction start 2030, LOIs with Finland, India, Italy, Poland, Slovakia and Slovenia.

[14] 30 MW LFR commissioning in 2031, 200 MW commissioning in 2033.

[15] Russia and Uzbekistan are planning to build 6 SMRs (type RITM-200N). Russia is building a RITM SMR in Yakutia, to be completed in 2027. Russia is building 6 SMRs in Kazakhstan with a total capacity of 180 MW (30).

[16] Russia is building a lead-based fast breeder reactor in Omsk (33).

[17] Russia builds and operates various SMRs on icebreakers and transport ships; fuel is 20 % enriched uranium (34).